Bahan

| Awak | Baja |

| Bérés | Séng Plated |

| Mandrel | Baja |

| Bérés | Séng Plated |

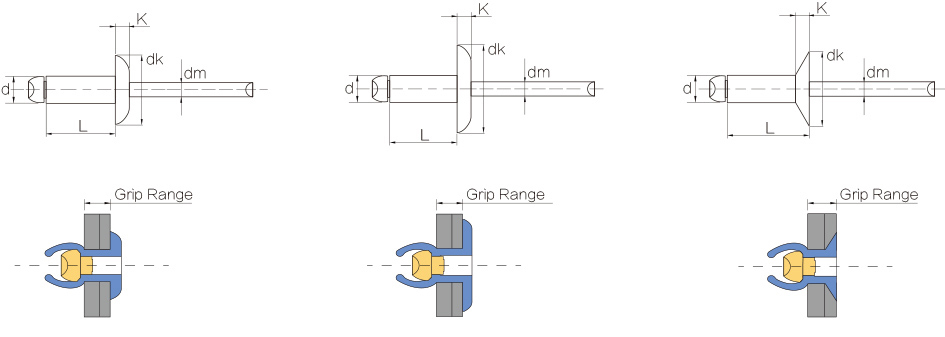

| Tipe Sirah | Kubah, CSK, Flange badag |

Spésifikasi

| D1 NOM. | DRILL NO. &UKURAN liang | ART.KODE | JARINGAN GRIP | L (MAX) | D NOM. | K MAX. | P MIN. | GELEK LBS | TENSILE LBS | ||

| INCI | MM | INCI | MM | ||||||||

| 3/32" 2,4 mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0,188" 4.8 | 0,032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0,250" 6.4 | 0,040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0,525 | 13.3 | |||||||

| SS48 | 0,376-0,500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,312" 7.9 | 0,050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0,550 | 14.0 | |||||||

| SS58 | 0,376-0,500 | 9.5-12.7 | 0,675 | 17.1 | |||||||

| SS510 | 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0,876-1,000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,375" 9.5 | 0,060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0,575 | 14.6 | |||||||

| SS68 | 0,376-0,500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0,876-1,000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6,4 mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0,080" 2.03 | 1,25" 32 | 1000 4450N | 1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0,376-0,500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0,501-0,625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| SS812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0,876-1,000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasi

baja buka tungtung rivets buta teu ukur betah ngagunakeun, efisiensi tinggi, noise low, bisa ngurangan inténsitas kuli sarta ciri séjén, tapi ogé sambungan tightness.Rivets baja bisa dibagi kana rivet sirah kubah, rivets countersunk jeung rivet sirah flange badag.Kakuatan tensile sareng geser tina rivet buta baja langkung luhur tibatan rivet aluminium standar.Hal ieu loba dipaké dina industri, bisa minuhan kaperluan paménta kakuatan tinggi.

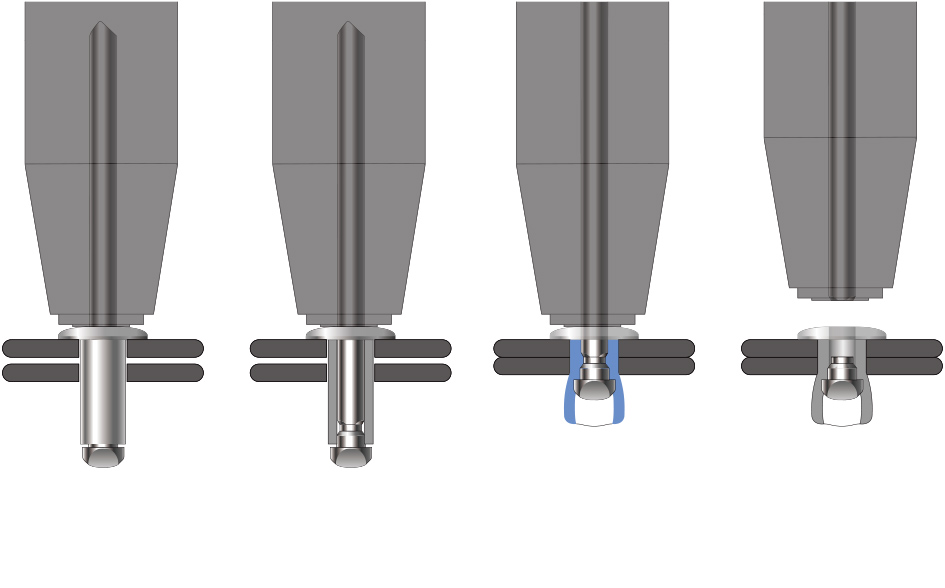

Masalah sareng alesan nalika nganggo rivet pop:

4.The pop rivet ditarik ngaliwatan: The mandrel rivet geus pinuh ditarik kaluar tina rivet nu, sarta mandrel nu pegat.Saatos riveting, ninggalkeun liang kosong dina rivet.

Alesan keur narik ngaliwatan: teuing rivet tegangan mandrel;diaméterna leutik caps mandrel;bahan riveting lemes;beungeut liang jero teuing lubricated.

5.Luncat sirah atawa kendang teu cukup: Nalika narik rivets, inti rivet Pops nepi lengkep, atawa rivet teu ngabareuhan.

Alesan pikeun fenomena ieu nyaéta: kontrol gaya tensile teuing low nalika inti kuku dijieun;awak riveting luhur (annealing henteu rata);

6. Bersantai sanggeus riveting: Saatos riveting, awak riveting leupas dina liang workpiece.