Bahan

| Awak | Aluminium(5050 5052 5056 5154) | (AL Mg 1%-1,5%, 2%-2,5% ,3%-3,5%,5%) | ||

| Bérés | Dipoles | RAL Warna dicét | ||

| Mandrel | Aluminium ● | Baja | Beusi sténless | |

| Bérés | Digosok ● | Séng Plated | Dipoles | |

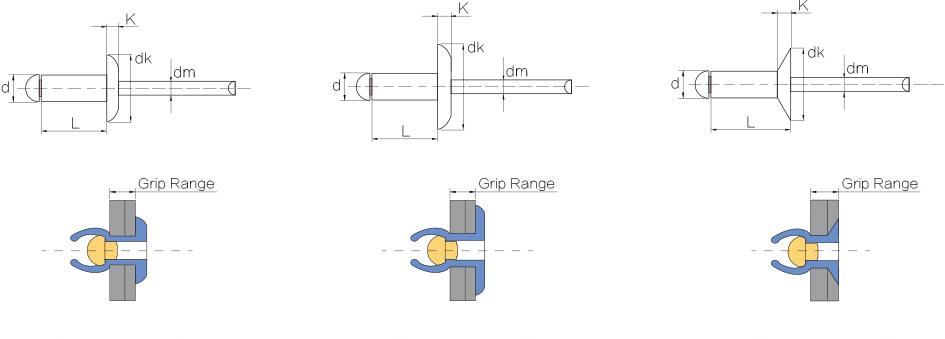

| Tipe Sirah | Kubah, CSK, Flange badag | |||

Spésifikasi

| D1 NOM. | DRILL NO. &UKURAN liang | ART.KODE | JARINGAN GRIP | L (MAX) | D NOM. | K MAX. | P MIN. | GELEK LBS | TENSILE LBS | ||

| INCI | MM | INCI | MM | ||||||||

| 3/32" 2,4 mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0,188" 4.8 | 0,032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3,2 mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0,250" 6.4 | 0,040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0,525 | 13.3 | |||||||

| AA48 | 0,376-0,500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0,501-0,625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4,0 mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0,312" 7.9 | 0,050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0,550 | 14.0 | |||||||

| AA58 | 0,376-0,500 | 9.5-12.7 | 0,675 | 17.1 | |||||||

| AA510 | 0,501-0,625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0,876-1,000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4,8 mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0,375" 9.5 | 0,060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0,575 | 14.6 | |||||||

| AA68 | 0,376-0,500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0,501-0,625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0,875-1,000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6,4 mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0,080" 2.03 | 1,25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0,376-0,500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0,501-0,625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0,876-1,000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasi

Rivet kabuka aluminium pinuh kami nganggo kawat alloy aluminium kualitas luhur.Saatos riveting, Éta moal karat.dibandingkeun sareng rivet biasa, inténsitas rivet rendah, janten cocog pikeun nyambungkeun bahan lemes.Aluminium pop rivets tiasa dibagi kana rivet sirah kubah, rivet countersunk sareng rivet sirah flange ageung. Sareng bahan alloy aluminium gaduh pilihan multi alu mg 2% 2,5% 3,5% jeung 5% (5052 5154 5056).

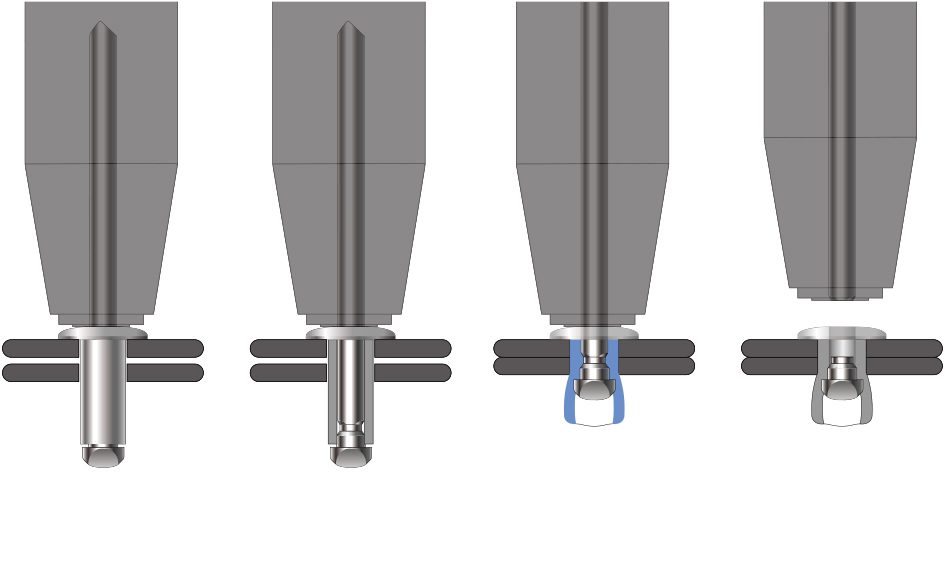

Fixpal buka tipe pop rivets boga kaunggulan operasi gampang, riveting alus teuing, penampilan geulis, sipat fisik tinggi.pilihan sampurna single-sided riveting.Aluminium rivets pop bisa loba dipaké dina sagala rupa kandaraan, kapal, manufaktur mesin, éléktronika, instrumentation, mesin dahareun, alat-alat médis, konstruksi, hiasan jeung wewengkon fastening lianna.

Masalah sareng alesan nalika nganggo rivet buta:

1. Burrs: Saatos riveting, mandrel peupeus kalawan burrs ngaliwatan liang rivet;atawa liang riveting protrudes ti luar pikeun ngabentuk burr spatula.

Anu ngabalukarkeun burrs: diaméter mandrel leutik;bahan rivet lemes;diaméter liang pangeboran tina workpiece badag teuing;spésifikasi muzzle tina gun rivet badag teuing;

2. Sirah paku ragrag: Saatos rivet ditarik, sirah rivet inti teu bisa dibungkus sarta ragrag kaluar tina rivet.

Alesan pikeun ragrag sirah rivet inti nyaéta: diaméter cap paku badag teuing;rivet leuwih pondok, sarta ketebalan rivet teu cocog.

3. rivet cracking: Saatos riveting, rivet ieu pulsed atawa sagemblengna ruptured.

Alesan pikeun cracking of rivet nyaéta: karasa kaleuleuwihan sanggeus annealing riveting atawa perlakuan unheated, hat inti kuku badag teuing.